BV-60VLF-G – Vertical Laminar Flow Cabinet

£2,871.67

£3,446.00 inc VAT

Contact us for the delivery lead time 01423 790039 or email us

Buyers outside of the UK are responsible for any VAT, tariff, duty, taxes, handling fees, customs clearance charges, and other fees required by their country for importing consumer goods. For more details please visit our delivery information page

- Description

- Additional information

Description

BV-60VLF-G – 60″ Vertical Laminar Flow Cabinet

Purair® Laminar Flow cabinets are designed to protect equipment and other contents of the work zone from particulates. The series is ideal for use with non-hazardous contaminants when flexible access to equipment in the work area is needed. Purair Laminar Flow cabinet series features the Air Science Multiplex™ ULPA Filtration technology which creates a clean work environment over a wide range of applications.

APPLICATIONS:

Purair Laminar Flow cabinets are suitable for applications that DON’T generate bio-hazardous materials and don’t need operator protection. These applications include:

- Mycology and Food Microbiology

- Plant and Mammalian Cell Culture

- Clinical Pharmacy and Hospitals

- Cleanrooms

- Semiconductor Assembly

- Pharmaceutical

- Aerospace

- Medical Device Assembly

- Research Laboratories

KEY FEATURES:

- Provides sterile work zone for aseptic techniques.

- Air cleanliness meets and exceeds ISO Class 4.

- All models use ULPA filters (99.999% efficient at particle sizes between 0.1 to 0.3 μm).

- Available in horizontal or vertical flow configurations.

- All models equipped with a stainless steel work surface.

- Chemically resistant and durable surfaces for long life

- Shipped fully assembled – no installation required

PERFORMANCE:

Multiplex ULPA Filtration provides high performance protection. The main filter gasket evenly seals the filter face to prevent bypass air leakage. Our pour-in-place silicone gasket out performs traditional style stick-on “dove-tail” gasketing. The high capacity air handling system delivers flow velocity of 0.4 m/s – 0.5 m/s. Purair VLF and HLF cabinets have an ULPA filter pressure gauge to measure filter performance.

DESIGN:

- Incorporates external rotor blowers

- Energy efficient design which operating costs and has low noise and vibration levels

- Designed for desktop use or installation on the optional mobile base stand

CONTROL:

The standard control panel features On/Off switches for blower, lighting, GFCI outlets, in addition to a Minihelic ULPA pressure gauge to measure filter performance. The standard UV control panel includes the same features as the standard control panel with the addition of a UV lamp key.

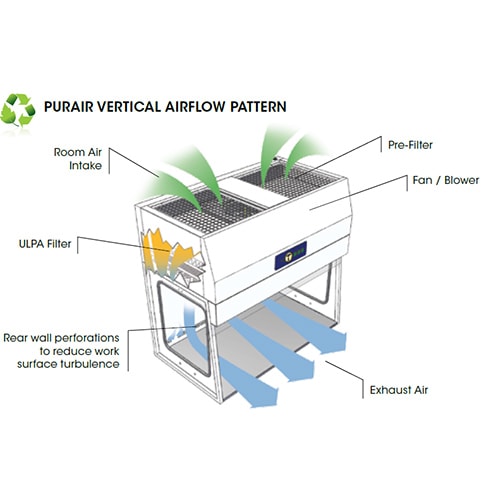

Consideration when choosing Vertical Airflow:

- The airflow on the Purair LF Series vertical flow cabinets directly strikes the work surface.

- Vertical laminar flow cabinets are manufactured with rear wall perforations that remove a small amount of air at the rear of the cabinet to reduce turbulence.

- In vertical flow cabinets, the ULPA filter is mounted above the work surface which provides a taller and deeper work space. This allows for larger equipment in the work zone without interrupted airflow.

- Vertical flow cabinets are more easily customised to specific applications.

Vertical Airflow Features:

- Room air enters from the top of the cabinet through a disposable pre-filter; this traps larger particles and increases filter life.

- Air is forced evenly across the ULPA filter in a stream of clean, uniform air within the work zone. This dilutes flushes airborne contaminants from the interior.

- A nominal filter face velocity of 0.4 m/s – 0.5 m/s ensures a sufficient number of air changes to maintain cleanliness within the work zone.

- The purified air travels down to the work zone in a vertical, unidirectional down-flow stream, exiting the work zone across the entire open cabinet front area after deflecting off the work surface.

- Rear wall perforations are designed to reduce work surface turbulence and minimise the possibility of dead air corners in the work zone.

Additional information

| Weight | 256 kg |

|---|---|

| Dimensions | Internal – 1524x694x718 (WxHxD) |

| Description | White epoxy coated steel frame, Interior – powder coated steel (optional Stainless steel available), Tempered glass side windows (not available on Stainless Steel model) Internal rotor motor low noise and low vibration blower, Main On/Off switch, fan speed control, Stainless steel work surface, filter blocked indicator, LED lighting, 120V 60Hz or 240 50Hz options, Polyester pre-filter, UPLA (99.999%) main filter |

| Ave. Air Velocity at Filter Face | 0.4-0.5 m/s (measured 150 mm from the filter) |

| Filters | Polyester Pre-Filter (85% efficient) |

| Noise Level dBA | <72 dBA |

| Standards & Compliance | Quality Management Systems: ISO 9001:2015 |