BV-PB60EN – Purair BIO Biological Safety Cabinet – Class II

£8,030.00

£9,636.00 inc VAT

Contact us for the delivery lead time 01423 790039 or email us

Buyers outside of the UK are responsible for any VAT, tariff, duty, taxes, handling fees, customs clearance charges, and other fees required by their country for importing consumer goods. For more details please visit our delivery information page

- Description

- Additional information

Description

Art. No: BV-PB60EN – Purair BIO Biological Safety Cabinet – Class II

The Purair® BIO biological safety cabinet (BSC) is designed for safety and performance in accordance with US and International Standards such as NSF/ANSI 49 which certify that Class II, Type A2 laminar flow cabinets are suitable for working with biosafety agents at levels 1, 2, 3 and 4. Our 4-foot models are certified by NSF. HEPA filtration of downflow and exhaust paths provides a primary containment work area for life science research, cell culture processing and other applications where protection of the user, the work product, and the environment and mitigation of cross-contamination on the work surface are needed.

ENHANCED PROTECTION

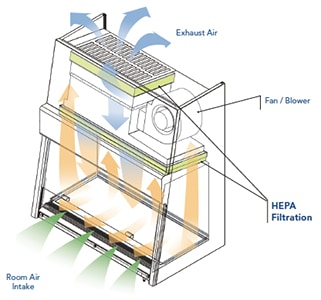

EASE OF USE – The Purair BIO maintains negative pressure inside the cabinet during operation to prevent contaminants from escaping the work area. HEPA filtration scours 70% of the incoming room air to protect the products, while the remaining 30% of the exhausted air is filtered by a second HEPA filter. Purair BIO cabinets provide ample workspace with environmentally sound operation, low energy consumption and user-friendly operation.

Single EC Blower Motor Design – The Purair BIO is designed with a single EC blower motor for ease of use, reliability and to promote low cost of ownership. Dual motor designs can introduce a number of problems, including unbalanced airflow, higher maintenance costs, longer certification processes and uneven filter loading. Airflow adjustments are simpler, operational costs lower and maintenance easier for BSCs equipped with single EC blower motors.

Flexibility – The Purair BIO includes multiple service connections for maximum flexibility. It includes duplex electrical outlets with splash-proof, UL listed covers. CSA certified service valves for gas, air and vacuum are also available. Maximum working pressure of 75PSI.

Operator Safety – The anti-ultraviolet, 6mm tempered glass ensures maximum protection for the operator.

Ergonomic Design – The user interface combines ergonomics, safety and aesthetics with a 10° angled window design that reduces operator head and elbow discomfort, as well as eye strain and fatigue.

APPLICATIONS

Purair BIO is designed to protect individuals, the environment and products from a variety of biological particulates. Specific applications include, but are not limited to: Life Science Research Sterile Product Preparation Biological Protocols

The Purair BIO includes industry-leading innovations and technology. It is easy to install, energy efficient, cost effective and safe.

PERFORMANCE

The supply/exhaust HEPA filters provide 99.99% efficiency at 0.3 microns (Class H14).

DESIGN

The Purair BIO is self-contained and does not require venting to the outside. Because filtered air is returned to the room, there is no increased load requirement for facility HVAC make-up air. This eliminates the cost of additional facility ductwork construction as well as HVAC maintenance and overhead.

VIRO-CUT™

Antibacterial Stainless Steel: The cabinet interior steel includes an anti-growth chemical embedded throughout. This ensures that regular cleaning and disinfecting activities will not degrade the antibacterial properties. The antibacterial effectiveness of VIRO-CUT stainless steel is validated by the JIS Z 2801 testing standard, one of the most commonly used testing methods in the world. The JIS Z 2801 testing method measures the growth of Escherichia coli and Staphylococcus aureus over a 24-hr period.

RELIABILITY

An innovative surrounded air intake grille keeps all contaminated air contained within the cabinet and isolated thanks to a double-wall design and negative internal pressure.

SELECTION

Purair BIO biological safety cabinets are available in 4 standard sizes. The slim profile hood design is the thinnest on the market and allows multiple laboratory configurations. Units are portable and may be moved from one location to the next with minimal downtime and without filter changes. Set-up, operation and filter maintenance are straightforward.

CONTROL

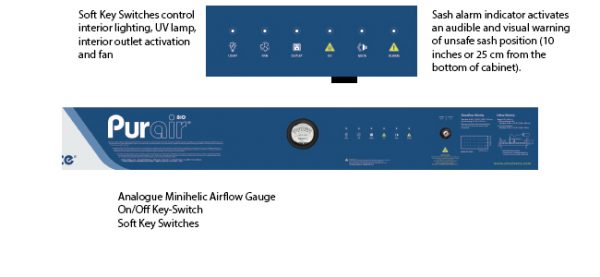

Purair BIO biological safety cabinet uses time-proven electronic controls instead of costly microprocessor controllers. Because all Class II, Type A2 cabinets must meet NSF standards for airflow, face velocity and other performance attributes, eliminating superfluous control and indicating devices simplifies operation and user interface while essential functions are maintained. As a result, the Purair BIO Series offers a cost-effective, efficient and compliant solution to biological safety cabinet applications in life science and associated uses.

CONTAINMENT AND PROTECTION

The Purair BIO maintains an airflow ratio of 70% recirculation to 30% exhaust to ensure operator protection. The inflow and downflow balance is precisely established, with no room air entering the work zone to prevent product contamination. Airflow patterns are precisely tuned and tested to create an optimum air curtain on the front aperture, maintaining personnel and product protection even during the unlikely event of severe inflow or downflow imbalances. The integrated HEPA filtration system provides clean air to the work surface in a gentle vertical laminar flow pattern, allowing the exhaust HEPA filter to trap biohazardous particles prior to the air being exhausted into the room.

HEPA FILTRATION

The Purair BIO uses HEPA filters to provide a range of high performance protection. These self-contained filters are designed to physically capture particles larger than 0.3 microns with >99.995% typical efficiency. The filters feature an integral groove filled with gel at the air inlet side, ensuring a perfect seal to the housing system. The aluminium frame guards against swelling typical of wooden framed filters. For unobstructed airflow and superior filtration, filters do not contain aluminium separators. A patented HEPA filtration lock maintains filter efficiency, minimizes the chance of leakage and prolongs filter life. The filters can also be changed from the front side of the cabinet quickly and easily.

ENERGY EFFICIENCY

The Purair BIO maintains one of the world’s highest performance ratings for a brushless DC motor. Additional benefits include: Better Apportioned Power. Over 80% of the EC motor output power is converted to kinetic energy to ensure sustainable energy savings over the life of the motor. Extended Filter Life. Balanced airflow and even distribution of downflow and exhaust paths promotes uniform filter loading to prolong filter life. Constant Feedback Motor Speed. The EC motor automatically adjusts speed to maintain compliant airflow at all critical points while compensating for filter loading and facility voltage fluctuations.

AIRFLOW

The Purair BIO is configured to comply with either NSF 49 (0.5m/s) or EN12469 (0.4m/s) criteria for airflow within critical points of the cabinet. In either model, the combination of HEPA supply and exhaust filters yields a fully integrated performance envelope for product, personnel and environmental protection from particulates.

Additional information

| Weight | 60 kg |

|---|---|

| Dimensions | 1634x789x1537mm (wxdxh) External |

| Features | A: Energy Efficient: The quiet, internal EC Brushless DC Motor ensures sufficient airflow across the work surface at all times while saving up to 86% over traditional PSC motors (based on internal testing). |

| Description | SUS#304 Frame construction with tempered glass window, EC Brushless DC Motor, Membrane push Switches, On/Off Switch, 2 Electrical outlets, HEPA filter, Optional Outlet filter, 240V 50Hz or 110V 60HZ, UL & CE approved |

| Ave. Air Inflow Velocity | 0.5m/s |

| Average Downflow Velocity | 0.30 m/s |

| Fan Motor Spec | 240V 50Hz, 110V 60Hz |

| Filters | Inlet Filter – HEPA (Class H14 – 99.99% @ 0.3micron) |

| Noise Level LAeq dB(A) | <60 |