BV-FPW – Downdraught Welding Fume Bench

Price varies depending on filter specification’ please contact our sales team for exact prices.

Contact us for the delivery lead time 01423 790039 or email us

Buyers outside of the UK are responsible for any VAT, tariff, duty, taxes, handling fees, customs clearance charges, and other fees required by their country for importing consumer goods. For more details please visit our delivery information page

- Description

- Additional information

Description

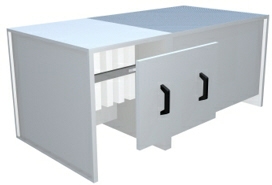

Part No: BV-FPW – Downdraught Welding Fume Bench

Heavy Duty Downdraught Filtration bench to contain and filter for a cleaner, healthier working environment within factories and engineering workshops etc.

For use in numerous situations where external venting is impractical but where contaminant of dust and debris capture is necessary.

The bench uses a unique spark-trap layout and 3 stage filter system to protect the final filter from sparks and allow the capture of hot materials.

Due to price variations depending on filter specification’ please contact our sales team for exact prices.

Applications include the filtration of dust and debris particulates emanating from:

- Welding

- Brazing

- Grinding

- Fettling

- Sanding

- Hand Plasma

Operation:

The BV-FPW range is of quality finish and well suited to installation in workshops and engineering sites where welding, grinding and fettling will take place.

It is suitable for surface loads up to 150kg. (Heavier loads up to 500kg can be catered for on request)

Optional accessories include: Remote fans for ducting to external vent system, electronic speed control, enclosures, “hours run” meter and castors to enable the bench to be easily moved around the work space.

Filtration:

This configuration features a unique 3 stage filter process. The first stage captures larger particles while the second stage features very low cost disposable pads to protect the main filter and extend its life to minimise filter costs; multiple direction changes promote drop out of the heavy particles which form most of the debris and dust in these operations. This configuration reduces the load on the final F9 media filter and hence reduces overall running costs.

The main main media is housed to the left of the working section and accessed through a service hatch in the form of a removable door. The two stage pre filters are housed in the main bench body.

Filters Sets include:

P: Welding fumes, Brazing, Grinding, Sanding, Hand Plasma and sparks, K: Grinding, Sanding, Hand Plasma and Fettling

Demonstrating adequate control of the risks to the health of employees students and the general public, from dusts, powders, mists, fumes and vapours is the fundamental requirement of the Control of Substances Hazardous to Health (CoSHH). For LEV information for employers visit the HSE website.

Additional information

| Weight | 53 kg |

|---|---|

| Dimesions | 2000x985x840 (WxDxH) – 1210×656 Vented Area, 2600x985x840 (WxDxH) – 1810×656 Vented Area |

| Description | Body of 2mm welded steel formed panels powder coated. Top of 3mm perforated powder coated mild steel. Positively clamped filter housing with filter access via removable top surface for cleaning and replacement. Integral 240v fanset (110V version available), IP56 motor enclosure, on/off switch, 3mtr mains lead and fused plug. |

| Air Volume at Free Air | 2600×985 units 4500m3/hr, 2000×985 units 3000m3/hr |

| Ave. Air Velocity at Filter Face | 1.5 m/sec |

| Filters | P: Welding fumes, Brazing, Grinding, Sanding, Hand Plasma and sparks, K: Grinding, Sanding, Hand Plasma and Fettling |