BV-DWS36-G Ductless Downflow Workstation

£2,235.00

£2,682.00 inc VAT

Contact us for the delivery lead time 01423 790039 or email us

Buyers outside of the UK are responsible for any VAT, tariff, duty, taxes, handling fees, customs clearance charges, and other fees required by their country for importing consumer goods. For more details please visit our delivery information page

- Description

- Additional information

Description

Art No: BV-DWS36-G – Ductless Downflow Workstation

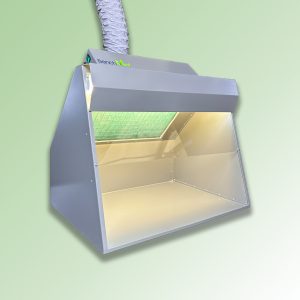

DWS Downflow Workstations are high efficiency ductless fume hoods designed to protect the user and the environment from hazardous vapours generated on the work surface. Unrestricted front and side access facilitates applications requiring complex and intensive operator involvement, while downward airflow in the chamber protects the operator. The DWS Downflow Workstation product line is based on an innovative Multiplex™ Filtration Technology that creates a safe work environment over the widest range of applications in the industry.

DUCTLESS TECHNOLOGY:

- The Eco-friendly Choice : Advanced carbon filtration technology offers a safe, high performance alternative to conventional ducted fume hood products for a broad range of applications.

- Environmental Benefits : Air Science ductless fume hoods isolate and trap chemical vapours to prevent ecological impact through release into the environment.

- Versatile : Each filtration system is selected for its specific application. The Multiplex Filter broadens the range of applications. Carbon filters are available in more than 14 configurations for use with vapours or organic solvents, acids, mercury and formaldehyde. HEPA/ ULPA filters can add to biological safety.

- Easy to Install : The ductless fume hood is self-contained and does not require venting to the out-side. Many units are portable and may be moved from one location to the next with minimal down-time and without filter changes. Set-up, operation and filter maintenance are straightforward.

- Energy Efficient : Because filtered air is returned to the room, no demands are required of the facility HVAC capacity for make-up air.

- Cost Effective : Facility ductwork, HVAC and construction costs are eliminated.

- Safe to Use : Workstation airflow and face velocity protect users from incidental exposures to fumes.

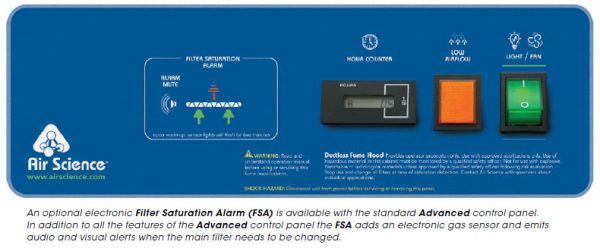

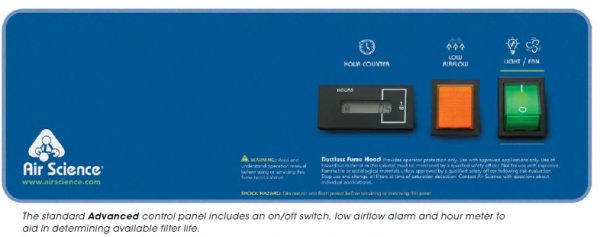

- Self testing : Electronic airflow monitoring assures continuous safety. An optional electronic gas sensor monitors carbon filter performance

MULTIPLEX™ FILTRATION TECHNOLOGY

- Multiplex Filtration consists of a pre-filter and main filter to create a combination of chemical and physical architecture customised to each application.

- The mechanical design enhances safety, convenience and overall value.

- The electrostatic pre-filter is accessible from within the cabinet.

- A filter clamping mechanism allows for the filter to be easily installed and ensures an even seal at the filter peripheral face at all times to prevent bypass leakage.

- The filter chamber prevents contaminated air from contacting internal cabinet mechanisms.

- The main filter type and installation date are displayed in a front-access window.

- The Air Science carbon filtration technique is based on enhanced, activated carbon particle formulations from specially selected, naturally occurring raw material superior to wood or other organic sources. The carbon is treated to attain the proper porosity and aggregate surface area and to react with several ranges of aerosolised chemicals moved through the filter by an air handling blower.

- The multiplex option permits one or more filtration options to be combined to meet a wider range of multiple-use applications. Multiplexing permits configuration for the capture of acids, bases and particulates such as biological aerosols when paired with HEPA or ULPA filters.

- The Air Science carbon filter is a self-contained assembly sized to fit the specified product model number, and configured to optimise airflow across 100% of the filter surface area for maximum efficiency, prolonged filter life, optimal diffusion and saturation capacity, and user safety.

BenchVent is the single source supplier for all pre-filters and carbon filters used in its products, plus those of many other manufacturers.

ENHANCED FILTRATION TECHNOLOGY

The EFT™ is a universal filtration system developed for use with a wide range of core chemical families. These include organic acids, aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, esters, aldehydes, ketones, ethers, halogens and others. Although the EFT system is weighted to accommodate these families, it can handle inorganic acids as well.

Additional information

| Weight | 126 kg |

|---|---|

| Dimensions | External: 914x580x800mm (WxDxH) |

| Features | Filter ID Window, Control Panel, Steel Support Frame, Electrostatic Pre-Filter, Airflow Alarm, Perforated Stainless Steel work surface, Optional Stand with locking wheels, Locked Filter door, Integral Lighting, Optional Side Panels and Front Sash, Complies to OSHA and ANSI, Available in Metal or Polypropylene |

| Description | White Epoxy coated steel frame and Head unit, Clear side panels, Centrifugal fan motor, UL-C-61010-1, CE Marked, 240V 50Hz or 110V 60HZ version, Low Airflow Alarm as Standard – monitors particle pre-filter, OSHA Standard -29 CRF, Safety and Health Regulations for General Industry, 1910.1450: Occupational exposure to hazardous chemicals in laboratories. Part B, definition, laboratory type hood. The DWS meets this definition when fitted with acrylic side window and front sash., Multiplex filtration system |

| Air Volume at Free Air | 493m3/hr |

| Ave. Air Volume at Hood Face | 0.4m/s |

| Fan Motor Spec | 240V 50Hz or 110V 60Hz (to specify) |

| Filters | Combination of Carbon filters to specify. HEPA/UPLA for fine dusts |

| Noise Level LAeq db(A) | <52 |