BV200-A – Single Arm Solder Fume Extraction System

£732.50

£879.00 inc VAT

Contact us for the delivery lead time 01423 790039 or email us

Buyers outside of the UK are responsible for any VAT, tariff, duty, taxes, handling fees, customs clearance charges, and other fees required by their country for importing consumer goods. For more details please visit our delivery information page

- Description

- Additional information

Description

Part No: BV200-A – Single arm Solder fume extraction system

Application:

- Electronics Hand Soldering

Included as standard:

- Combine HEPA/Gas filter

- Pre-filter

- installation kit

- 1x arm

What can the BV200-A Solder Fume Extraction and Fume Filtration Unit be used for?

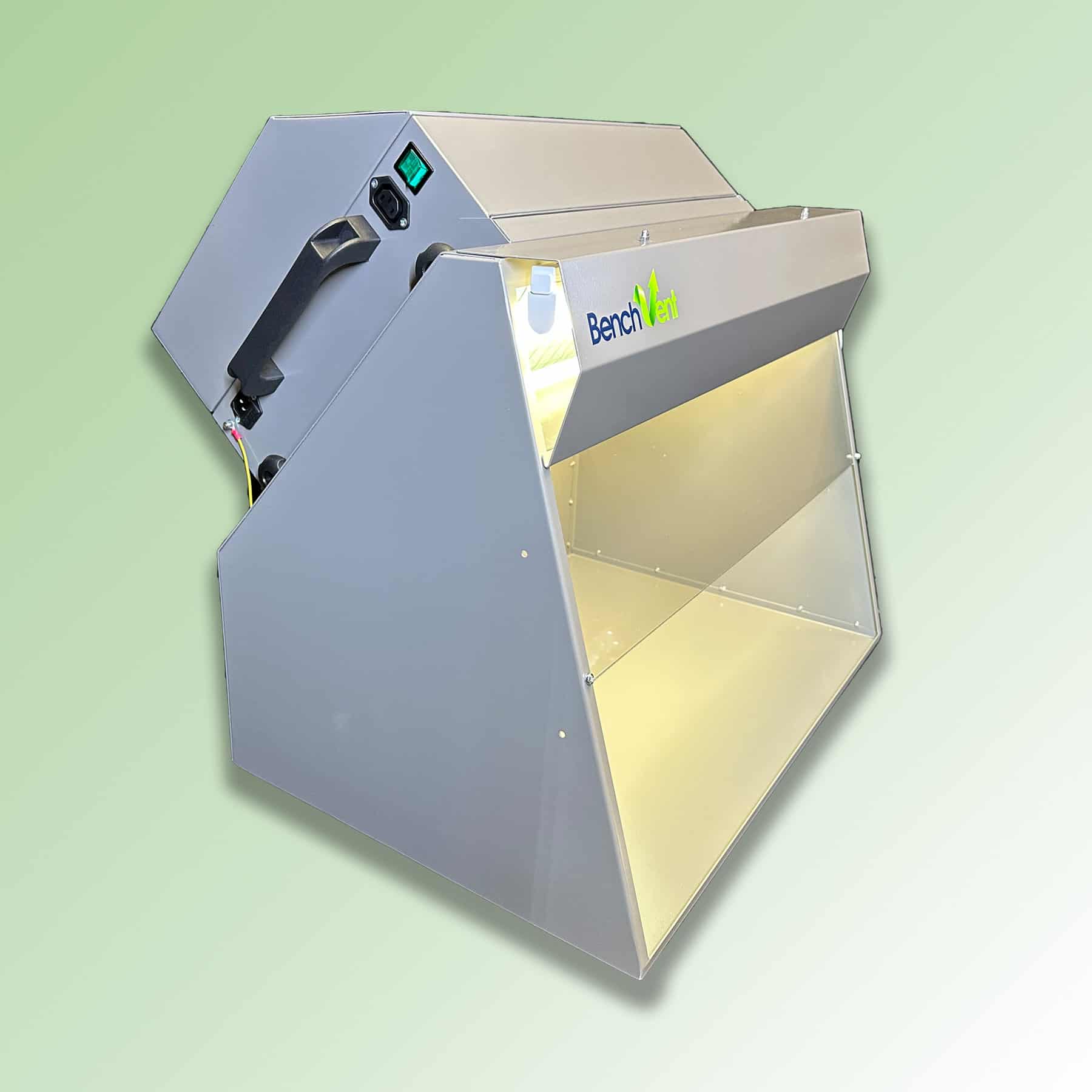

The BV200-A allows the end user to capture, contain and filter soldering fumes for a cleaner, healthier working, environment within electronic design, rework, design and technology areas. These portable, single station, plug and play systems are complete with ESD extraction arm and installation kit to enable the operator to be set up quickly and easily.

Key Features

- No major installation costs required making them easy to move with the workbench if factory layouts change.

- Comes complete with a flip top flush sealing mount plate, 50mm ESD Stay Put extraction arm and installation flex and bracket.

- Low noise level and fully integrated filtration with long life filters are ideal for changing production demands.

- Ideal for high volume, at source, soldering applications where tip extraction is not required.

Why buy the BV200-A Benchtop Solder Fume Extraction Unit?

Quiet in operation and assembled in seconds. It’s floor standing fan/filter box is fitted to desk/bench by way of flexible installation pipe and table bracket. The stay put arm is fitted on top of the desk/bench and manoeuvred into required extraction position. It comes with a 12 month return to base warranty.

How are soldering fumes filtered and extracted?

The particulate (intake) filter is a 99.997% HEPA filter which provides gas filtration via deep, granulated, carbon gas filter. The unit also benefits from a blocked filter indicator to facilitate correct filter change times to maintain efficient filtration. Through the process of filtration, adsorption and dilution, operator exposure to potentially hazardous soldering fumes substances is vastly reduced or eliminated.

These units are designed for immediate operator protection from concentrations of airborne contaminants whereby all gases, fumes, vapours and particulates on top of the unit are drawn into the intake filter. Cleaned air is exhausted to the base of the bench. Higher grade filters are available on request.

Demonstrating adequate control of the risks to the health of employees students and the general public, from dusts, powders, mists, fumes and vapours is the fundamental requirement of the Control of Substances Hazardous to Health (CoSHH). For LEV information for employers visit the HSE website.

Additional information

| Weight | 60 kg |

|---|---|

| Dimensions | 420x290x270mm (hxwxd) |

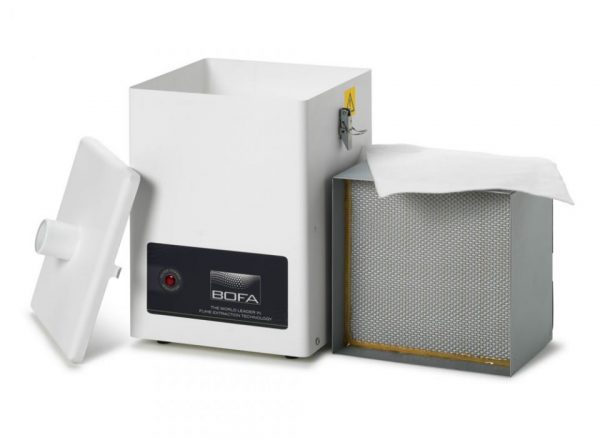

| Description | Steel construction fan/filter unit finished in white – Floor mounted fan/filter unit – Centrifugal fan motor – 50mm ESD stay put extraction arms – 3mtrs x 50mm installation flexi tube – table bracket – flip top flush sealing mounting plate – Filter Blocked indicator. |

| Hose Dimensions | 1.4mtrs x 50mm dia |

| Arm Dimensions | 650mm x 50mm dia |

| Ave. Air Velocity at Filter Face | 180 m3/hr |

| Fan Motor Spec | 230V 50Hz, 110V 60Hz Option |

| Filters | Carbon/HEPA |

| Noise Level LAeq dB(A) | 54 db(A) |